Optimization

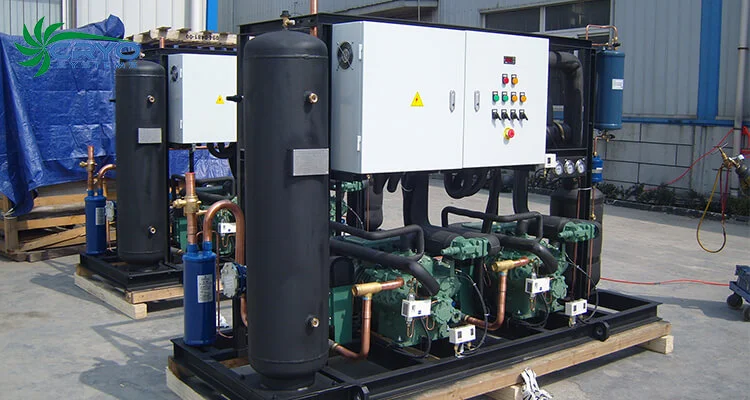

Bitzer compressor rack uses multiple compressors in one system, bigger cooling capacity, safer, easier install and control. What’s more, each compressor is independent and run according to system loading, so higher efficiency and longer lifetime.

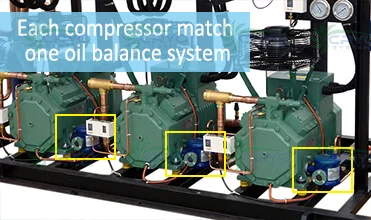

Balanced oil level is very important for the compressor rack. If compressor no oil, it’ll damage soon.

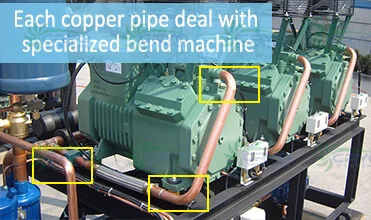

Specialized bend machine deal technology, 100% no leaking problem. In corners part, we use bending instead of copper corners.

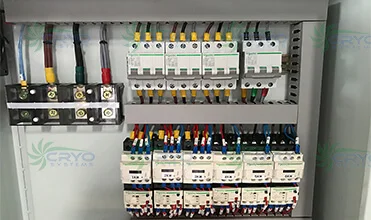

For compressor rack, each compressor run based on the machine loading, so accurate pressure controller is very important.

It’s equipped with Schneider electric, with multi protections including phase protection, phase lack, over current, too constant starting of compressor, discharge temperature, etc.

Compressor type | Bitzer compressor and Screw compressor |

Horsepower | 18HP~300HP |

Cooling type | Air cooled, water cooled, evaporative |

Refrigerant type | R134a, R404a, R507a or R22 |

Place to assemble | Indoor/out door(concrete construction building/steel construction building). |

Voltage | 220V/50HZ, 220V/60HZ, 380V/50HZ etc |

Controller | Automatic electric controller, PLC |

Quality Assurance | 2.8MPA pressure test during produciton |

Customer info: This project is in a tropical country, with ambient temperature up to +38C most of the year. Considered the machine stability and efficiency, we advise compressor rack systems.

Order info:

Compressor rack: 4x18HP Bitzer semi-hermetic compressors, with EC fan, with economizer.

Cold room dimension 32x12x5meter with ante room, 150mm PU panels with 0.6mm color plate.

Why compressor rack is better than a single compressor?

Compared to the single compressor, the compressor rack is safer, more power-saving, easier to maintain and install. Price is a little higher than the single compressor, but for the long term considering, it is a very economical efficiency.

Which condenser type is better? Air cooled or water cooled?

If you could offer water with good quality and adequate supplies, water cooled condenser is a better choice; If not, air cooled condenser will be better.

How does each compressor work on the compressor rack?

Compressor rack works based on the cold room loading. If the low loading in the cold room, one compressor runs; when more loading is inside the cold room, two or three compressors run.

If one compressor was wrong, will it impact the working of other compressors?

No, as compressors can work independently, so one compressor wrong will not impact other compressors’ working.

What is the warranty for the refrigeration unit?

One-year warranty. But with the original new Bitzer/Copeland compressor, the lifetime is 8~10 years at least.

Do I need a compressor rack for my cold room projects?

Check our blog to find is it suitable for your cold room to use a compressor rack

We accommodate any size of cold room and cater to your unique requirements.

Share your project requirements with us, and we’ll promptly reach out to you. We eagerly anticipate the opportunity to collaborate with you!

© 2024 Cryo Systems USA. All rights reserved

Cryo Systems USA specializes in delivering top-notch cold room solutions and comprehensive services.

We offer three popular cold storage designs: freezer room/processing room/blast freezer room.

We also provide customization services for cold rooms. Send your cold room request to Cryo Systems USA now and let us tailor the perfect solution for you!