XPS board

As shown in the figure below

SBS water barrier

It is mainly waterproof.

PE film

For moisture-proof

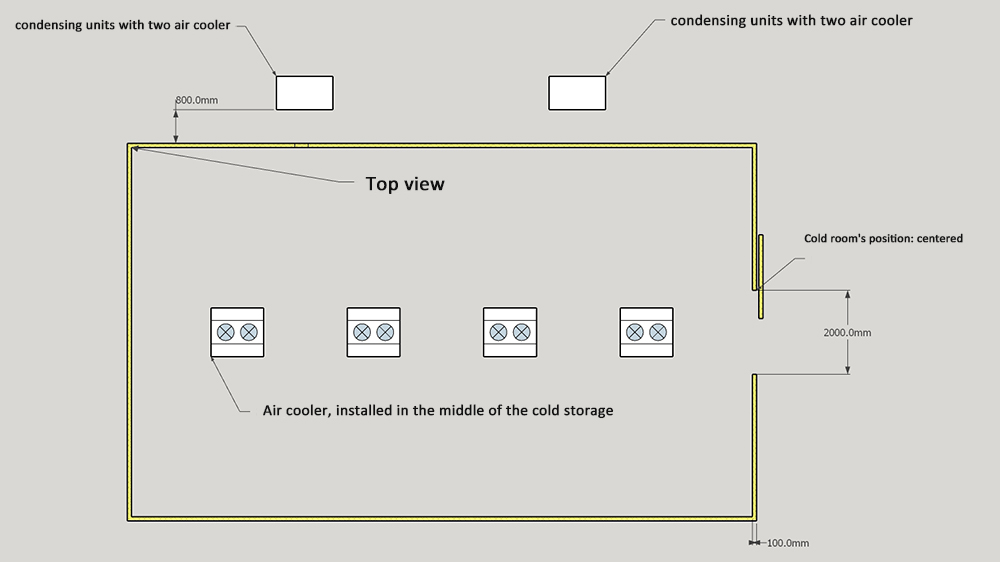

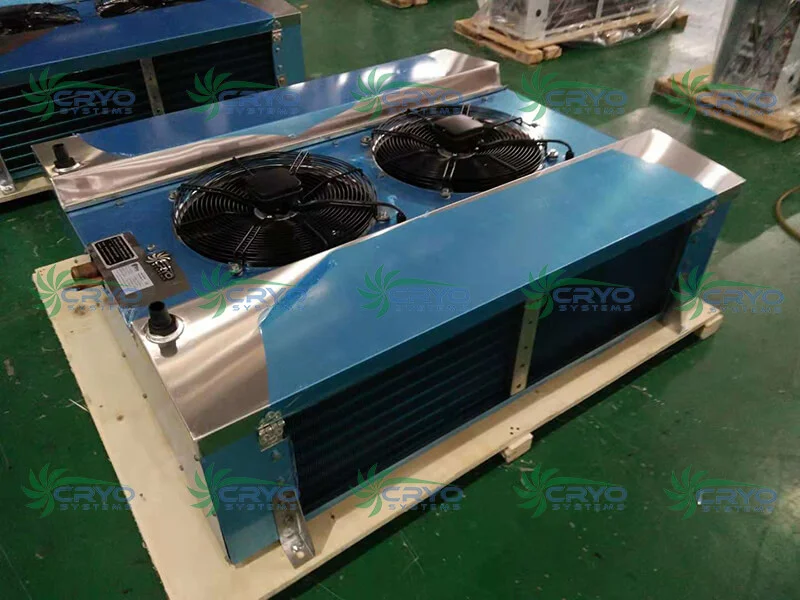

The processing room primarily handles seafood, chicken, butter, chocolate, and other food products. The temperature is typically set between 10°C to 18°C to accommodate the presence of personnel working inside.

If you lack an engineer to design your cold room, we can provide the expertise you need. Each cold room project we undertake is meticulously crafted by our experienced engineering team with decades of experience. We ensure that every design we present is thoroughly discussed with you to meet the majority of your requirements.

If the installation of cooling machines appears complex or local refrigeration engineers are unavailable, opt for our expert cold room builders who offer turnkey services.

We accommodate any size of cold room and cater to your unique requirements.

Share your project requirements with us, and we’ll promptly reach out to you. We eagerly anticipate the opportunity to collaborate with you!

© 2024 Cryo Systems USA. All rights reserved

Cryo Systems USA specializes in delivering top-notch cold room solutions and comprehensive services.

We offer three popular cold storage designs: freezer room/processing room/blast freezer room.

We also provide customization services for cold rooms. Send your cold room request to Cryo Systems USA now and let us tailor the perfect solution for you!